NFS Surface Filter

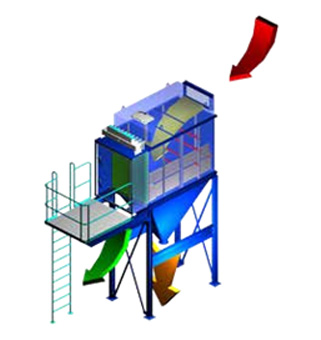

The NEOAIRTECH NFS range of reverse air filters comprises a series of modular filter units up to 5000 m² filtration area. The filter system provides continuous automatic reverse air cleaning with a constantly low differential pressure at extremely low operating costs.

The filter housing is constructed of tough reinforced welded steel sheets in a modular design. Large front doors enable quick and easy access for maintenance operations.

The following are the key advantages of reverse air filter:

- High separation efficiency

- Gentle cleaning process

- Low operating costs

- Low differential pressure

- Easy to maintain system

- Space-saving concept

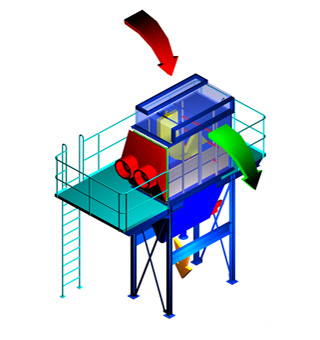

NFCT with compressed air cleaning

The NEOAIRTECH NFCT range of jet filters operates by compressed air cleaning and is able to accommodate a filtration area from 14 m² up to approx. 2000 m². This economic and compact filter type has small filter surfaces with low required space and also with a lower required height. Except for few details, this surface filter corresponds to the design of the NFD.

The following are the key advantages of reverse air filter:

- High separation efficiency

- Low differential pressure

- Easy to maintain system

- Space-saving concept

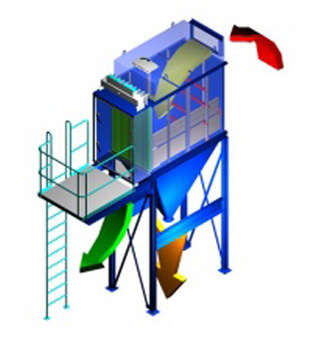

NFD with compressed air cleaning

The NEOAIRTECH NFD range of jet filters operates by compressed air cleaning and can accommodate a filtration area of up to 2000 m² in one filter housing. Custom-built to specification, this dust extraction offers lower capital investment cost to a similar reverse air cleaning filter, at least, if smaller sizes are concerned. The filter housing is constructed of tough reinforced welded steel sheets in a modular design. Large front doors enable quick and easy access for maintenance operations.

The following are the key advantages of reverse air filter:

- High separation efficiency

- Low investment costs

- Well-integrable filter housing

- Easy to maintain system

- Space-saving concept

NFK with/without cleaning

The NEOAIRTECH NFK range heat exchangers or surface cooler is designed to cool hot and dusty exhaust gases (approx. 550°C) from melting furnaces e.g., cupolas, rotary furnaces, shaft furnaces, and as a result, allows the use of more economical filter media. For cooling of gases, ambient air supplied by fans is fed through the horizontally installed cooling pockets. In addition to that, coarse dust particles are separated utilizing deflection and in special cases, the cooling surfaces are automatically cleaned.

The following are the key advantages of reverse air filter:

- Cooling of hot gases from approx. 550°C

- High cooling rate

- Pre-separation

- Low operating costs

- Low-pressure loss

- Space-saving concept

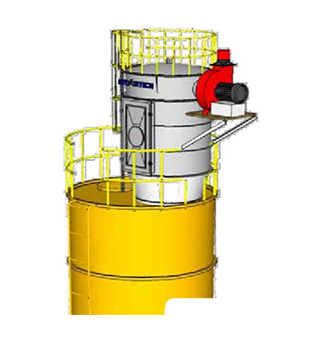

Silo Vent Filter

The NEOAIRTECH The silo vent filters operates by compressed air cleaning, which can be mounted either on top of the silo or floor mounted. This compact filter type has cartridges for filtration & compact in construction.

The following are the key advantages of reverse air filter:

- High separation efficiency

- Low differential pressure

- Easy to maintain system

- Compact construction